Central interface between IT and OT

Scalability

i-flow combines MQTT and NATS in a unified architecture — delivering maximum performance and scalability from the shopfloor to the enterprise.

High Availability

Redundant broker instances and automatic failover ensure continuous operation in production-critical IT/OT environments.

Central Governance

Central management of namespaces, payload structures and authorizations via the i-flow Hub. Consistent across all IT and OT levels.

"The i-flow software offers the fastest communication times between PLCs and IT systems and is the most scalable and comprehensive solution we have tested on the market."

Philipp Steuer (IT Administrator, Hirschvogel Group)

IIoT data

publish, transform & subscribe

publish, transform & subscribe

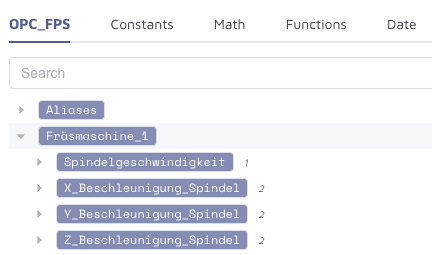

Publish data - with just a few clicks.

Model and publish your data once in the i-flow Broker (“publish once”). From there, the data can be subscribed to and processed by any number of systems (“distribute everywhere”). True to the principle of “publish once, distribute everywhere” with maximum efficiency.

IIoT data

publish, transform & subscribe

publish, transform & subscribe

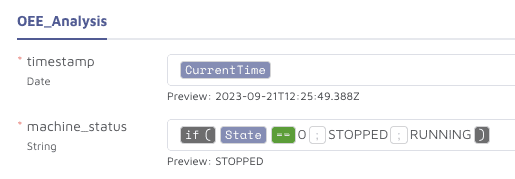

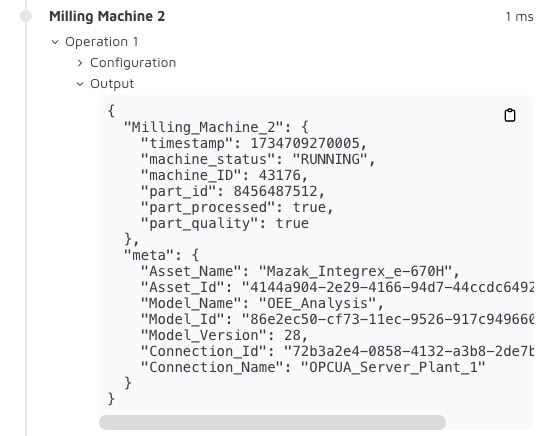

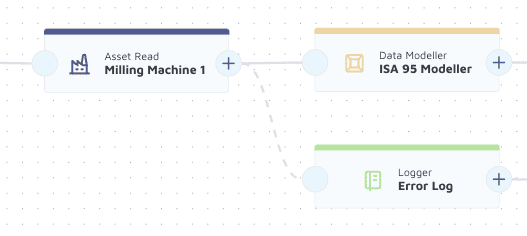

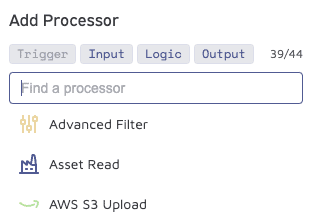

Transform data - without code.

Aggregate machine, sensor and IT data. Enrich it and publish the results back to the broker. The broker reliably distributes the results to all connected systems, such as SCADA, MES or ERP.

IIoT data

publish, transform & subscribe

publish, transform & subscribe

Subscribe to data - from any number of target systems.

Subscribe to relevant data and events in the i-flow Broker from any number of systems and use-cases. This allows you to create near-real-time communication between the systems in your factory.

MQTT & NATS: Best-in-Class Combined

One size fits all? Not for OT and IT. Different requirements demand different strengths. i-flow brings together best-in-class open-source messaging technologies in a unified architecture.

MQTT for the Shop Floor

Lightweight yet reliable (QoS, retained) – ideal for sensor and machine integration on the shop floor.

NATS for Global Workloads

Cluster and supercluster architectures federate plants and regions into a global, highly scalable Unified Namespace.

Performance & Scalability from Shop Floor to Enterprise

Using MQTT and NATS, i-flow scales for extreme throughput, minimal latency and native federation at factory and enterprise level.

Optimized for Industrial Scaling

Extremely high throughput, minimal latency and native horizontal scaling for factory and enterprise UNS.

Global Federation

NATS Supercluster connects several clusters to a common namespace for multi-factory, multi-region and multi-cloud UNS.

High availability for Production-Critical Use Cases

High availability is an integral component. i-flow ensures continuous operation even if individual nodes fail.

High Availability is Not an Add-on

- Genuine distributed broker guarantees fail-safe operation

- No external components required

- NATS JetStreams ensure persistence and data availability

- Consistent system configuration, even in the event of node failure

Security-by-Design

i-flow is developed according to the security-by-design principle and optimized for use in critical IT/OT environments.

Central security functions

- Centralized security governance via the i-flow Hub

- Encrypted communication and certificate-based authentication

- Central role-based access control (RBAC)

- Integration into central identity providers (e.g. Microsoft Entra ID)

- Optimized for segmented IT/OT networks

400 Mio. Data Operations per Day

Over 400 million data operations per day in production-critical environments demonstrate the scalability of the software and the deep trust that customers place in i-flow.

Whether PLC, sensor or ERP data, i-flow provides the basis for a modern IT/OT architecture in manufacturing companies.

i-flow Operations this month: -

Over 400 million data operations per day in production-critical environments demonstrate the scalability of the software and the deep trust that customers place in i-flow.

Industrial Unified Namespace (UNS)

i-flow provides the key components for scalable system integration in factories based on an open, event-based and scalable architecture – the Industrial Unified Namespace (UNS). The architecture has a modular design and consists of three modules: i-flow Hub, i-flow Broker and i-flow Edge.