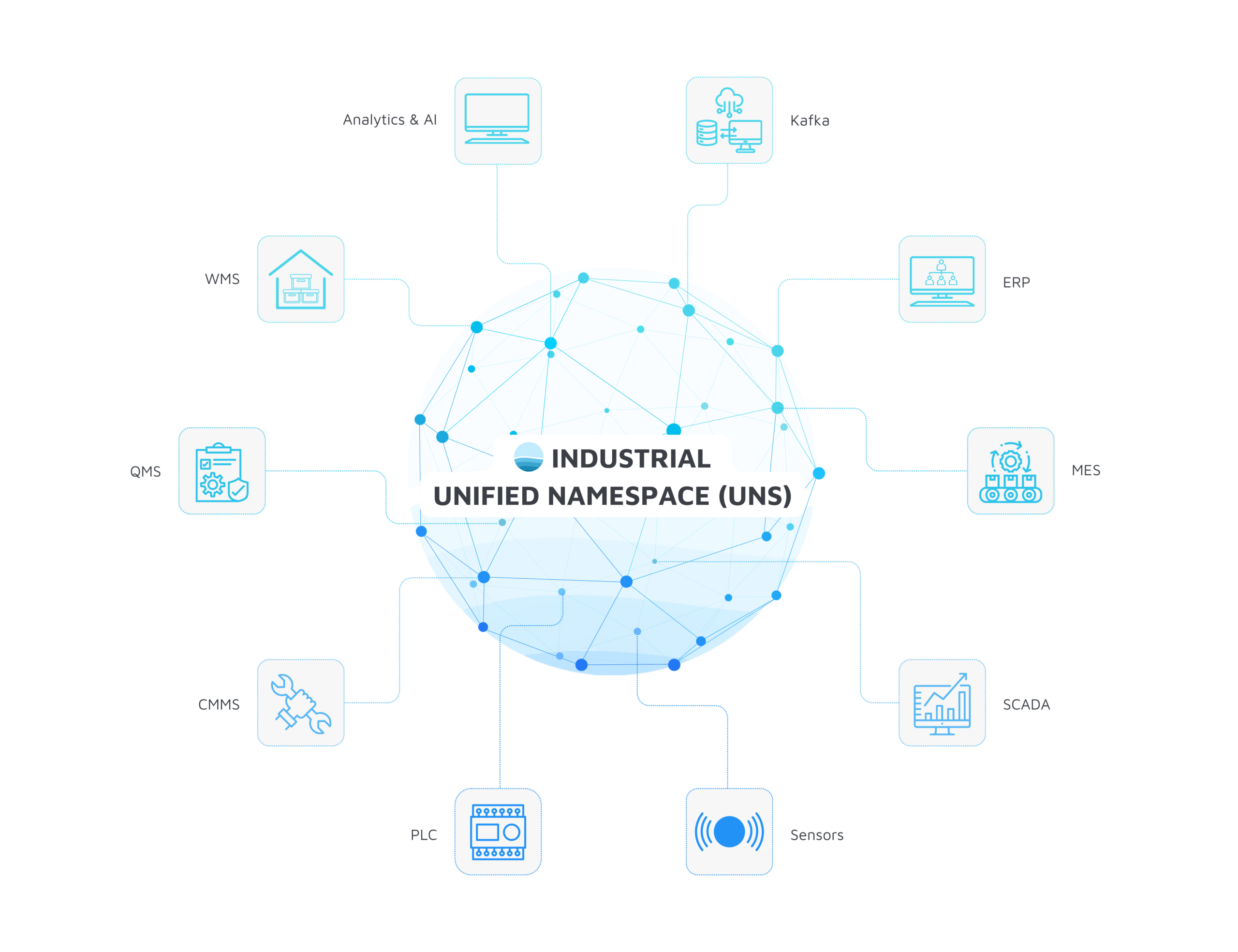

Meet the new way of connecting factory systems.

Complex data handling between OT and IT? Break through the complexity with i-flow’s Industrial Unified Namespace (UNS) and orchestrate data across factory boundaries – revolutionary simple! i-flow is more than just a tool. i-flow is empowerment.

100% customer satisfaction

The i-flow software impresses.

100% On Premise

Your company, your data.

The solution to the data problem in the industry.

Data Availability

A heterogeneous IT/OT system landscape slows down your ambitions? Seamlessly connect all systems with over 200 i-flow connectors.

Data Quality

Why waste resources on tedious data cleansing? With i-flow, you receive clean factory data via a single interface.

Turn Complexity Into Simplicity.

The i-flow software provides a single interface to clean factory data. And thanks to our innovative low code technology, revolutionary simple.

The old way

- Individual 1:1 integration

- Pull-/Push communication

- High integration costs

- Data silos

- Heterogeneous data

- Closed architecture

The new way

- Scalable m:n integration

- Event-based communication

- Minimal integration costs

- Central access point

- Harmonized data

- Open architecture

Working with i-flow sets new standards: i-flow combines highly intuitive software that enables rapid success with the ability to scale easily.

The i-flow software has fundamentally changed our technical capabilities, allowing us to harness the full potential of the data generated by our machines.

This is further enhanced by i-flow's exceptional customer service, ensuring thorough support with fast response times.

i-flow's data hub allows anyone to work with factory data while ensuring control over access to critical resources.

The i-flow software offers the fastest communication times between PLCs and IT systems and is the most scalable and comprehensive solution we have tested on the market.

And thanks to the intuitive design, we can scale with our own expertise. i-flow has truly revolutionized the way our systems interact.

Meet us at the HMI 2025 in Hanover!

How i-flow seamlessly scales with your requirements?

400 Mio. Data Operations per Day

Over 400 million data operations per day in production-critical environments demonstrate the scalability of the software and the deep trust that customers place in i-flow.

Whether PLC, sensor or ERP data, i-flow provides the basis for a modern IT/OT architecture in manufacturing companies.

i-flow Operations this month: -

Over 400 million data operations per day in production-critical environments demonstrate the scalability of the software and the deep trust that customers place in i-flow.