Case study

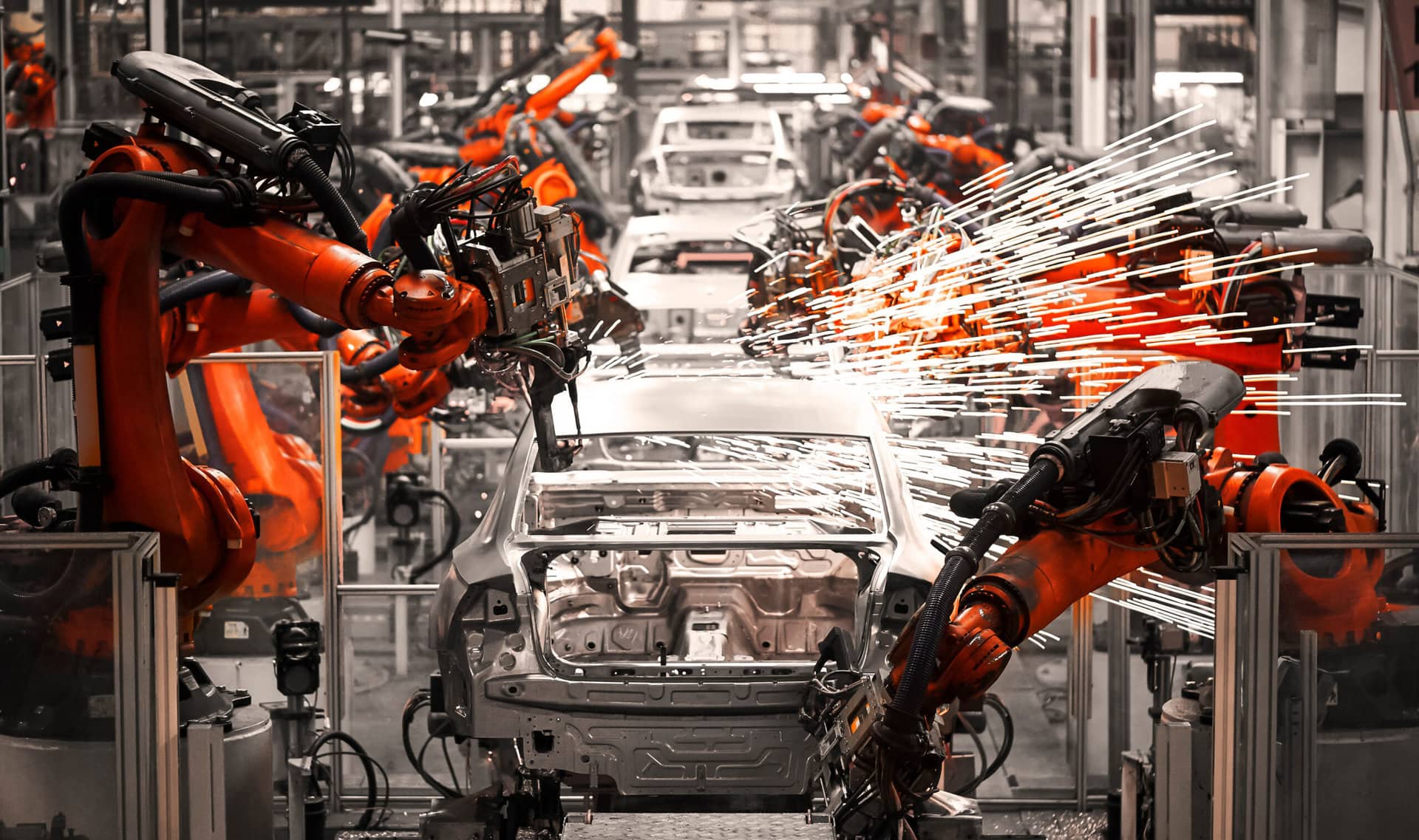

The leading Tier 1 automotive supplier from the USA is known for its extensive global production network and the important role it plays in the supply chain for OEMs worldwide. As a Fortune 500 company, it has distinguished itself through innovative product development and manufacturing excellence. With state-of-the-art manufacturing facilities on several continents, the supplier is a core partner for automotive manufacturers around the globe, delivering customized solutions and high-quality components that shape the mobility of tomorrow. Its strength lies in its in-depth industry knowledge and technological leadership, allowing the company to continuously contribute to the evolution of the automotive industry.

Manual processes between individual production steps of the value chain not only led to costly errors and inefficient processes, but also to unplanned downtimes along the production lines. Among other things, the tedious manual booking of materials in the ERP system and the release of production steps after quality checks were symptomatic of the existing bottlenecks. At the same time, the customer was looking for a solution that would enable scalable networking between the heterogeneous machine park and the existing enterprise and cloud systems.

To automate the processes, the customer chose the Industrial Unified Namespace (UNS) from i-flow. In addition to the realization of a future-proof edge-to-cloud architecture, the reasons were in particular the revolutionary ease of use of the i-flow software. In just a few months, the customer has connected 60+ systems (e.g., PLCs, databases, SAP, AWS) and automated over 20 million operations daily with the i-flow software. This led to a significant acceleration of the customer’s digitization and automation initiatives.

For security reasons, the customer assigned individual permissions (e.g. write / read) to the various user groups (several OT groups + IT) to essentially manage access to individual systems (e.g. SAP reads, PLC writes). This prevents non-authorized users from writing to production-critical systems. In addition to i-flow’s revolutionary ease-of-use, the customer benefits from completely new dimensions in OT / IT system integration. Thanks to i-flow, bidirectional and event-based communication between the various systems was made possible, ensuring a seamless exchange of data and information. For example, material flows are now synced with SAP in real time, production-critical data is shared with OEMs via the cloud, and production steps are released automatically based on prior quality checks.

Realized system architecture:

The implementation of i-flow resulted in significant benefits for the customer. Thanks to the rapid integration of various systems and automation of production processes, productivity was increased by up to 8% (in direct production and indirect office areas) after only a short time. Manual errors were eliminated, minimizing unplanned production downtime by 38% and significantly increasing plant OEE.

Results:

The successful implementation of i-flow at our customer illustrates the potential of process automation at the interface between OT and IT. Thanks to flexible and scalable OT/IT system integration that enables the automation of processes, companies can significantly increase their competitiveness and optimize their operations. The i-flow team is proud to be a trusted partner of the Fortune 500 company.

Scaling Industry 4.0 with i-flow