The Unified Namespace (UNS) is becoming increasingly important as the central interface between IT and OT in the manufacturing industry. End-to-end machine integration in the Unified Namespace (UNS) is essential in order to create an efficient and scalable data infrastructure. However, machines and systems are often connected manually, which is time-consuming and complex. The lack of standards and proprietary interfaces from different machine manufacturers are particularly problematic and make seamless integration difficult. This results in isolated solutions that slow down the exchange of data between machines and IT systems and hinder the scalability of Industry 4.0 applications.

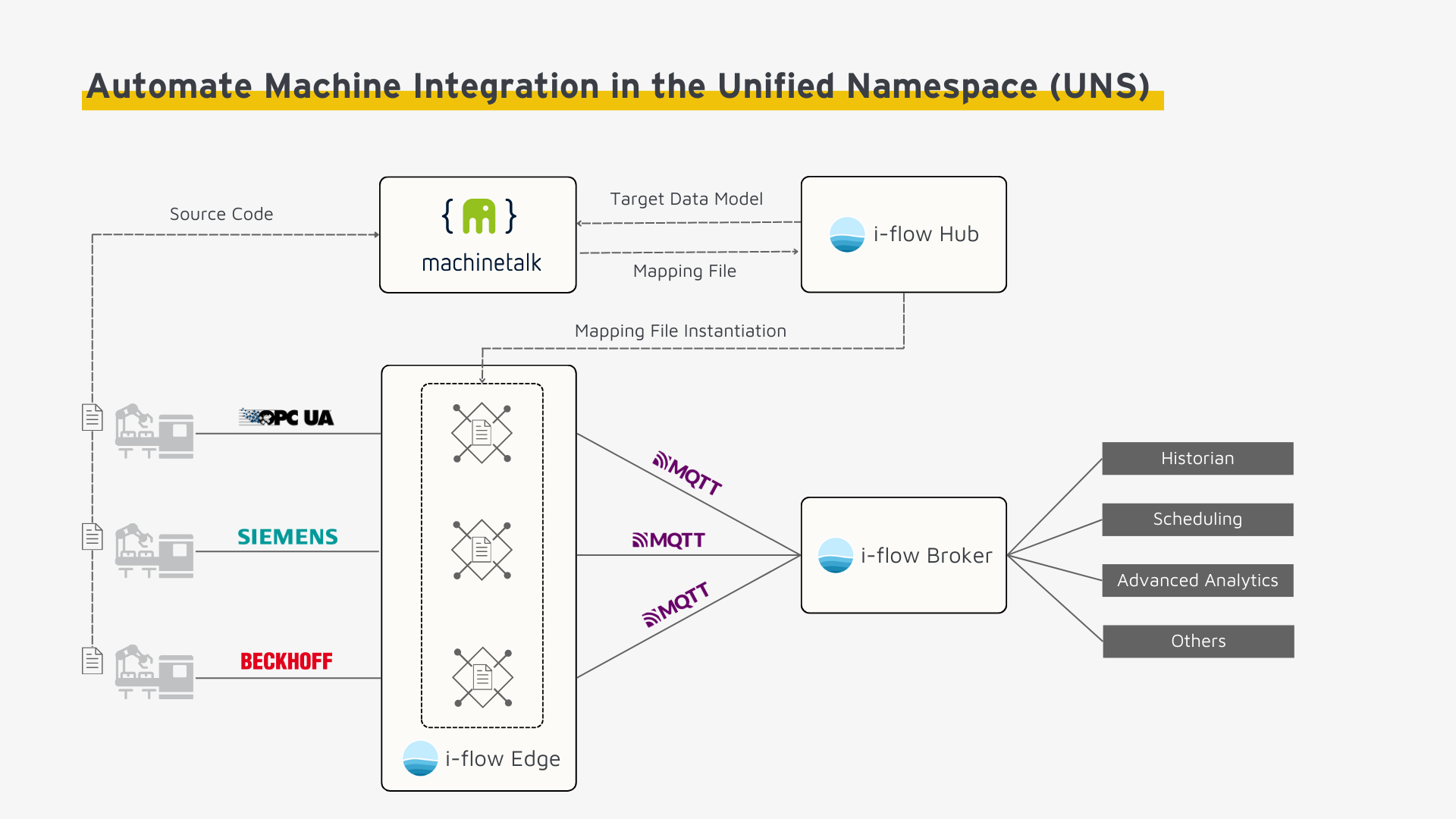

In this case study, we show how machinetalk and i-flow fully automate machine integration in the UNS. The combination of both technologies creates an efficient, flexible and future-proof solution that considerably simplifies machine connection and enables consistent, standardized data communication.

What is the Unified Namespace (UNS)?

The Unified Namespace (UNS) is a central real-time data platform that serves as a single source of truth for production and IT systems. It enables efficient, scalable and manufacturer-independent integration by connecting OT, IT and cloud systems via a standardized, event-based data model. This breaks down data silos and considerably simplifies and accelerates system integration. With the three key components Edge, Broker and Hub, i-flow offers a powerful solution for setting up a Unified Namespace (UNS). Detailed information on the UNS and its benefits can be found here.

The challenge of machine integration in the Unified Namespace (UNS)

The integration of machine data into the Unified Namespace (UNS) is crucial for consistent and scalable system integration in the manufacturing industry. In practice, however, this process often proves to be challenging. The main obstacles are

- Proprietary interfaces: Many machines – both existing and new – are operated with manufacturer-specific control interfaces that make standardized data integration difficult. While OPC UA is often seen as a universal solution, an OPC UA interface specified in the specifications is often not sufficient in practice to ensure seamless integration into an UNS based on MQTT. Find out more here.

- Lack of standardization: Global standards for the representation of machine data are lacking or are too complex for practical implementation. In many cases, standards are defined by manufacturers, while the actual data users are hardly involved. As a result, many of the existing standards are difficult to understand, impractical or not established across the board.

- High manual effort: Due to the lack of standards, machine operators often only have the option of manually interpreting PLC address spaces, either with their own resources, through external service providers or in cooperation with the machine manufacturer. Mapping this data into the target data structure of the UNS is time-consuming, expensive and error-prone, which makes further integration and use of the data considerably more difficult.

Automated integration with machinetalk and i-flow

machinetalk and i-flow offer an automated and scalable solution for seamless machine integration in the Unified Namespace (UNS). The previously manual and time-consuming integration of machines is replaced by an intelligent combination of automatic data mapping, preparation and standardized provision.

This is done in three central steps:

- Automatic creation of interface descriptions with machinetalk

machinetalk analyzes the control source code, existing documentation and the target specification and automatically creates a structured interface description for mapping machine data. This is prepared graphically for the experts and remains fully editable. After final coordination, it serves as the basis for the configuration of the i-flow UNS. - Seamless integration into the UNS with i-flow

As soon as the interface description is available, integration into the UNS takes place via the i-flow Hub. This ensures instantiation in an i-flow Edge, which performs the following tasks:- Read out the OT data via the control addresses determined by machinetalk (e.g. from an OPC UA structure).

- Transformation of the data into the desired target format.

- Provision of data via MQTT in the UNS for standardized, cross-system use.

- Scalable data distribution and bidirectional communication

The i-flow Broker distributes the processed data to all connected production and IT systems, such as MES, ERP or cloud applications. Bidirectional communication is also possible so that IT systems can write data back to the machine control system via the defined interfaces.

Thanks to this automated integration, the interface description remains dynamically adaptable at all times and can be expanded or modified via machinetalk as required.

Advantages of combining machinetalk and i-flow

The automation of machine integration in the Unified Namespace (UNS) with machinetalk and i-flow has significant advantages, including:

- Reduced integration effort and lower error rate: Automated machine integration reduces the time and costs required to connect new machines or adapt existing systems by an average of 84%. At the same time, the error rate is reduced by 93%, as manual mapping processes are no longer necessary.

- Flexibility for new requirements: Changes to the required data structures can be made directly in the target data model of the UNS. New data points or additional machine information can simply be reloaded in the control system and automatically integrated into the UNS – without time-consuming manual configuration.

- Future-proof and scalable solution: The combination of machinetalk and i-flow enables sustainable expandability of the UNS. New machines and additional use cases can be integrated without high integration costs.

Conclusion

The integration of machines into the Unified Namespace (UNS) is a key prerequisite for connected, data-driven production. Until now, this process was associated with a high level of manual effort, complex interfaces and a lack of standards. This significantly limited the scalability and efficiency of Industry 4.0 solutions. The combination of machinetalk and i-flow fully automates machine integration in the UNS for the first time. The intelligent analysis and automatic creation of interface descriptions drastically reduces the effort required to connect new machines or adapt existing systems. At the same time, standardized provision via the i-flow UNS enables consistent, manufacturer-independent data communication.

machinetalk is a subsidiary of IoT Werk GmbH. The founders – Rainer and Peter – have decades of experience with data use cases in the production environment. machinetalk is the first software solution developed in close cooperation with customers to drastically reduce the high costs of networking projects. machinetalk is universally applicable and is appreciated by manufacturers and operators alike. We focus on companies in Europe because we believe that data-based production can compensate for locational disadvantages such as high labor and, in some cases, energy costs.