In the context of Industry 4.0, system and data integration remain the Achilles heel of many organizations. ICONICS in the Unified Namespace (UNS) addresses this critical challenge by providing a modern integration architecture. Based on the open architecture of i-flow, PLCs, devices and IT systems can be connected across sites via the UNS with ICONICS Genesis64. The result: a decoupled, event-based architecture that serves as the foundation of a smart factory. This joint case study by RBT Technology and i-flow shows how ICONICS can be connected in the Unified Namespace (UNS) and the benefits that result: faster commissioning, lower integration costs and better scalability.

What is ICONICS Genesis64?

ICONICS Genesis64 is a modern SCADA/HMI platform used for visualizing, monitoring, and controlling industrial processes. It provides robust capabilities for data connectivity, processing, and visualization – both on-premises and in the cloud. With support for open standards like OPC UA and MQTT, Genesis64 is ideally suited for integration into connected industrial environments. As part of a Unified Namespace architecture, it plays a key role in enabling real-time visibility across OT and IT systems (image source). Learn more about ICONICS Genesis64 here.

What is the Unified Namespace?

The Unified Namespace (UNS) is a centralized data model that structures all real-time operational and business data. From machines on the shop floor to cloud-based enterprise systems within a unified information layer. Built on open protocols like MQTT, the UNS ensures that all systems access the same, consistent, and up-to-date data. This shared architecture allows for seamless, decoupled integration of IT and OT systems – a decisive step towards a flexible, scalable smart factory. You can find more details about the Unified Namespace here.

Technical Architecture

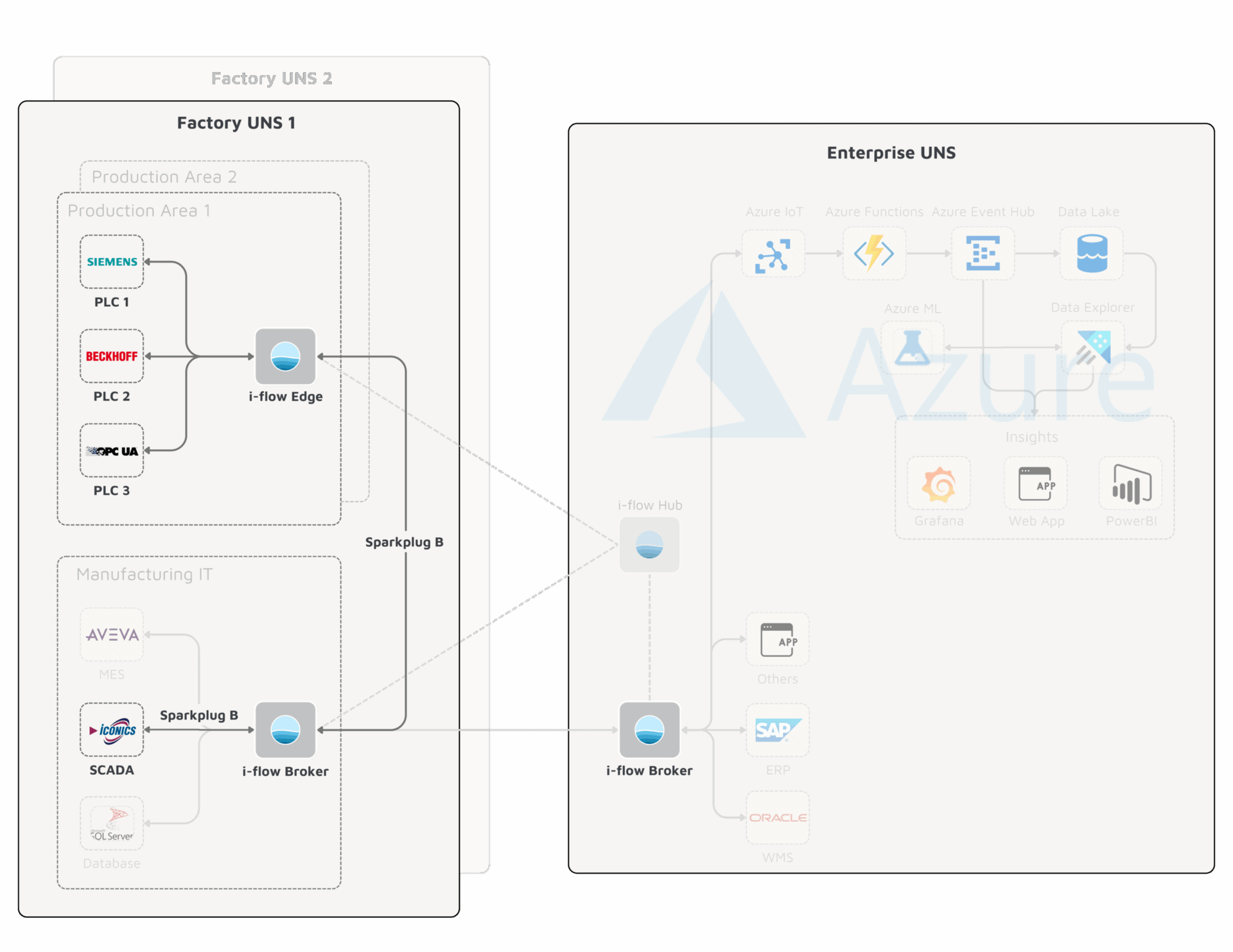

RBT Technology and i-flow integrate ICONICS Genesis64 in a Unified Namespace (UNS) architecture that spans from the shop floor to the enterprise level. This structured and scalable setup enables seamless communication between edge devices and central IT systems. The example architecture below, designed for multi-site operations, shows how data flows from PLCs through i-flow to SCADA and enterprise applications. This architecture is organized into three core components:

- PLC connectivity with i-flow Edge

- Factory Unified Namespace (UNS) with i-flow Broker and ICONICS as data consumer and producer in the UNS

- Enterprise UNS with central IT applications that also act as data consumers and producers in the UNS

1. PLC Connectivity with i-flow Edge

At the OT level, i-flow Edge plays a central role in connecting PLCs and devices to the Unified Namespace (UNS). The lightweight, high-performance software runs directly on industrial PCs, servers, or gateways near the machines. It natively supports industrial protocols like Modbus TCP, Siemens S7, OPC UA, and Beckhoff TwinCAT – making it easy to integrate both legacy and modern systems into the UNS architecture.

What does that mean? i-flow Edge harmonizes data directly at the source. Regardless of protocol or vendor, machine data is transformed into a standardized model with consistent units and synchronized timestamps. This real-time normalization minimizes latency and ensures clean, structured data within the unified namespace.

Practical example: In a packaging area, multiple controllers operate via OPC UA and Modbus. A single i-flow Edge instance connects them all, captures the data, standardizes its format, and publishes it to the UNS. Typical data points such as batch numbers, quantities, weights, or machine states become instantly available to all connected systems, from ICONICS SCADA to MES and reporting tools. This illustrates how ICONICS in the Unified Namespace enables seamless integration across heterogeneous environments.

2. Factory Unified Namespace (UNS) with i-flow Broker and ICONICS

In the factory, the i-flow Broker acts as the central data hub. All data captured by i-flow Edge is transferred via MQTT into the local Unified Namespace (UNS). Instead of creating point-to-point connections between each PLC and every application, data is published once to the broker. Authorized systems – such as SCADA, MES, analytics, or other local applications – can then subscribe to the needed data streams, without modifying PLC or gateway configurations. This “Publish Once, Distribute Everywhere” model drastically reduces integration effort, simplifies onboarding of new systems, and enables high scalability. Even millions of data points and devices can be connected without disrupting the existing architecture. ICONICS in the Unified Namespace benefits directly from this approach, allowing new ICONICS applications to integrate seamlessly across the global network – without custom interfaces or complex setup.

Sparkplug B: Plug-and-Play for ICONICS in the Unified Namespace

To enable standardized integration, ICONICS in the Unified Namespace leverages Sparkplug B. Sparkplug B is an MQTT-based specification for industrial data exchange. It ensures consistent topic structures and payloads, including timestamps, quality flags, and data types. As a result, all participants interpret information the same way.

A standout feature is auto-discovery: when a new i-flow Edge comes online, it sends a “Birth” message with all available tags. ICONICS detects this automatically and registers the device and tags. No manual configuration needed. For example, if a sensor at Factory1/Line3/DeviceA publishes a temperature value, ICONICS instantly creates the corresponding tag in its archive. Engineers can immediately use this data in HMI views, trend charts, or alarms.

Sparkplug also supports bidirectional communication, enabling ICONICS to send commands like setpoints or control instructions back to PLCs. This transforms SCADA from a pure consumer to an active participant in the UNS.

3. Enterprise UNS Integrating Central IT Applications

At the enterprise level, a central message broker connects all sites into a consistent, company-wide Unified Namespace (UNS). Core IT systems such as ERP, MES, BI tools, or cloud analytics platforms access standardized production data directly from the UNS. As a result, systems like SAP or analytics platforms can subscribe to production data from the broker – whether for KPI monitoring, quality analysis, or traceability. As part of a bidirectional setup, IT systems can also write back data into production processes via the same structure and without the need for site-specific or custom interfaces. Thereby, ICONICS Genesis64 acts not only as a local SCADA system, but also as a data publisher and subscriber within the global architecture.

The key benefit: Data is published once and instantly made available across all systems and sites. New plants, machines, or applications can be integrated rapidly – without having to adapt existing systems. New digital use cases can be piloted centrally and scaled globally, all based on the consistent data model within the Unified Namespace.

Technical Advantage over Traditional Architectures

The combination of i-flow, ICONICS Genesis64 and the Unified Namespace (UNS) offers clear technical advantages over traditional automation architectures.

1. Single-Source-of-Truth for Factory Data

With ICONICS in the Unified Namespace (UNS), all IT and OT systems access a unified interface regardless of whether the data originates from a Siemens S7 controller, an OPC UA server, or an SQL database. As each data point enters the UNS, it is automatically standardized in structure, format, and units. Once available in the broker, all data follows a consistent model, creating a single source of truth for both local factory systems and enterprise-wide IT applications.

Example: An optimization platform can monitor multiple lines and locations in parallel through one standardized interface enriching OT data with ERP or quality data in real time. At the same time, control commands can be sent back to production via the same UNS structure.

2. Increased Network Security and Efficiency

ICONICS in the Unified Namespace (UNS) leverages MQTT for communication offering clear security and performance advantages over traditional poll/response protocols like OPC UA. Since MQTT does not require open inbound ports in critical OT networks for bidirectional communication, the attack surface is significantly reduced. This enhances cybersecurity across the production environment.

Additionally, MQTT uses an event-driven communication model (“report by exception”), which means only actual data changes are transmitted. This minimizes unnecessary traffic and keeps the network load low, even in large-scale deployments. The result is a robust, efficient, and secure data exchange between IT and OT systems, optimized for modern industrial requirements.

3. Real-Time Access at Any Scale

Iconics in the Unified Namespace (UNS) enables real-time data access across the entire infrastructure — from the machine level to the cloud. By using MQTT’s event-driven communication model, every data change is forwarded instantly, with minimal latency and no polling overhead.

Unlike traditional poll/response systems, each data source sends its information only once to the broker, regardless of how many systems subscribe to it. This approach keeps the load on PLCs low while maintaining responsiveness. The architecture is designed to scale effortlessly, supporting thousands of devices and millions of data points without compromising performance.

4. Improved Maintainability

Iconics in the Unified Namespace (UNS) enhances system maintainability through full transparency and self-awareness. Using the Sparkplug B protocol, the system communicates vital status information via built-in “birth” and “death” messages. This makes it immediately clear which devices are online or offline crucial for fast troubleshooting. When a device fails, the cause can be quickly pinpointed without manual investigation. Additionally, i-flow Edge continuously provides diagnostic data, including connection quality and the health of the full data pipeline. Combined with integrated logging and monitoring, this offers IT and OT teams end-to-end visibility, from the PLC to the SCADA layer and into the cloud.

New devices or applications can be added without increasing system complexity, ensuring long-term operational stability in a growing UNS environment.

5. High Change Flexibility

The architecture enables agile change management across the entire organization. All i-flow Edge nodes are centrally managed via the i-flow Hub, allowing new data points or logic to be deployed quickly and uniformly across all sites. This centralized approach eliminates the need to manually configure local gateways or devices, reducing errors and administrative effort. As a result, companies gain the flexibility to scale and adapt their digital infrastructure without disrupting existing operations. An essential capability for any future-ready smart factory.

Economic Benefit

The combination of ICONICS and the i-flow Unified Namespace (UNS) delivers measurable economic value. The architecture lowers integration costs, accelerates implementation timelines, and improves production performance. This unlocks a clear competitive advantage for Industry 4.0 leaders.

1. Lower Integration Effort and Reduced Costs

With the publish/subscribe model of the Unified Namespace, each data point is connected once and becomes instantly available to all relevant systems – whether SCADA, MES, ERP, or BI. This eliminates the need for complex point-to-point interfaces or custom integrations. All systems access the same standardized data via a shared interface. Thanks to i-flow’s low-code platform, new data sources and applications can be added rapidly without programming. This dramatically reduces integration time and costs.

2. Reduced Operating Costs (TCO)

The open, vendor-agnostic architecture of the UNS ensures long-term flexibility. Machines, PLCs, or software platforms can be replaced or upgraded without reengineering existing data flows. This decoupled structure reduces system complexity compared to traditional landscapes with numerous point-to-point connections and lowers the cost of future adaptations, expansions, or migrations. In practice, this reduces the total cost of ownership (TCO) for industrial data infrastructure significantly.

3. Faster Implementation and Shorter Time-to-Value

New machines and production lines can be integrated in a fraction of the time. ICONICS in the Unified Namespace automatically detects new devices and their tags via Sparkplug eliminating manual configuration. What once took weeks can now be accomplished in hours. Projects move faster, and new assets deliver value sooner, enabling a faster return on investment (ROI).

4. Foundation for the Smart Factory

The true value of the Unified Namespace lies in its role as a centralized, real-time single source of truth. It provides a unified IT/OT interface that simplifies the deployment of smart factory use cases such as condition monitoring, and advanced analytics. For instance, predictive maintenance solutions can simultaneously access machine data (e.g., temperature, vibration, uptime) and ERP data (e.g., orders, batches) across sites without additional integration. This seamless access to contextualized data forms the backbone of a smart factory.

Conclusion: Iconics in the Unified Namespace (UNS) as the key to the smart factory

ICONICS in the Unified Namespace (UNS) delivers a future-proof integration strategy for Industry 4.0. By combining ICONICS Genesis64 with the MQTT-based i-flow architecture, organizations gain a unified, scalable, and real-time data infrastructure that bridges IT and OT seamlessly. The result is a single source of truth that reduces integration effort. It also increases operational agility, and accelerates digital transformation across all levels – from PLCs to enterprise IT. As demonstrated in this joint case study by RBT Technology and i-flow, ICONICS in the Unified Namespace is not just a technical solution—it’s a strategic enabler for the smart factory of tomorrow.

About RBT Technologies: RBT Technologies as a company from Ljubljana, Slovenia provides products and solutions for automation and digitalization of industrial environments, infrastructure and buildings. Company has long-term experiences in industrial automation and robotics, in last couple of years broad expertise is being upgraded with digitalization products and I4.0 projects.