Industrial production faces the challenge of controlling increasingly complex processes in real time while remaining flexible to change. Traditional AI models such as LLMs reach their limits, as they cannot process live data or autonomously trigger actions during operation. AI agents close this gap by combining language models with memory, tools, and interfaces to make decisions, coordinate processes, and act directly within the Unified Namespace (UNS). This enables new levels of automation, efficiency, and intuitive human–machine interaction in the factory.

What is an AI Agent?

Large Language Models (LLMs) have been at the center of the AI discussion for some time now. These foundation models are trained with large amounts of data and act as powerful text prediction engines: they accept an input and generate a unique response. However, there are two serious limitations for industrial applications:

- No real-time access: LLMs cannot directly access current machine data, sensor values or external systems.

- Static knowledge: New facts or domain knowledge require re-training, a resource-intensive and slow process.

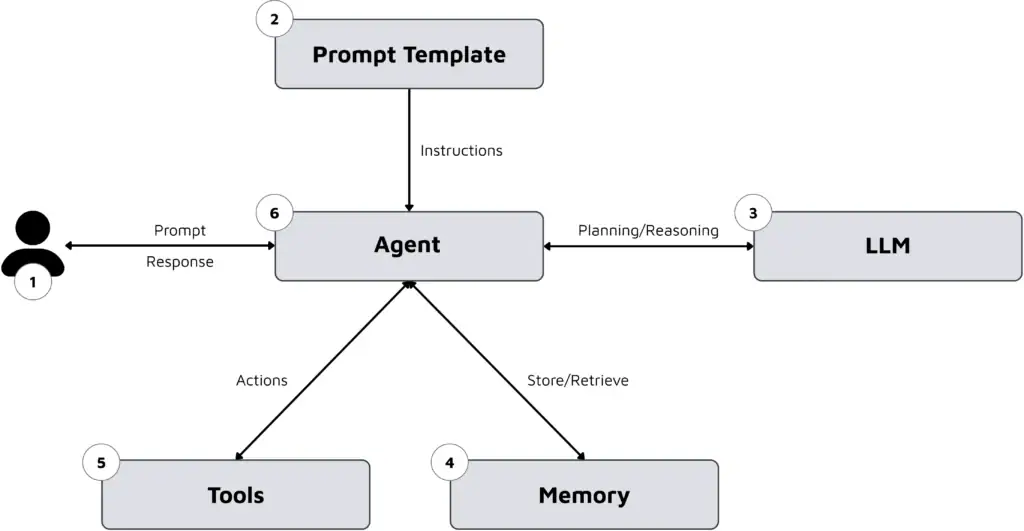

This is where AI agents come in. They use LLMs as one of several components:

- User input: Human input, e.g. questions or commands that initiate the agent.

- Prompt template: Standardized instructions ensuring repeatable and consistent processes.

- LLM (Large Language Model): Language model that understands and generates texts. It provides the linguistic and semantic foundation, but is static without additional components.

- Memory: Short- and long-term storage enabling context-aware actions across longer processes.

- Tools: External systems (e.g. APIs, databases, control systems) the agent uses to query data, execute actions or interact with machines.

- Agent: Central hub that integrates all components, makes decisions, and controls processes.

The diagram highlights the difference: an AI Agent receives user input, interacts with an LLM, and connects to tools and memory. This enables not only information processing but also action execution, data storage, and retrieval. AI Agents thus evolve from pure language models into active systems: they consume data, make decisions, and coordinate actions in real time.

- LLM = Static knowledge module for text generation

- AI Agent = Dynamic action system that combines LLMs with logic and interfaces for effective operation in production environments

Practical Examples in Manufacturing

AI agents in manufacturing go beyond detecting issues or optimization opportunities. They can also initiate and coordinate follow-up actions within defined safety and operational limits. Through natural language interaction, operators can query status, run what-if scenarios, or confirm actions.

1. Predictive Maintenance with AI Agents

Predictive AI monitors equipment data in real time to detect early signs of potential failure (e.g. subtle changes in vibration or temperature patterns). For example, AI can track sensor data from rotating equipment. If a bearing failure is predicted in 42 hours, the AI agent can create a work order in the CMMS, initiate the procurement of the replacement part and coordinate the repair plan. This ensures that the problem is fixed while operations continue to run efficiently.

Difference to conventional AI: Conventional predictive maintenance tools are often single-stage. They can detect anomalies and issue alerts. However, they rely on humans to decide on the next steps and take action. An AI agent augments this by assessing the situation, selecting the optimal response and coordinating follow-up actions across the system. In short:

- Today’s AI = “Here’s a problem you should check.”

- AI agent = “A problem was detected; repair and parts are planned, the log is updated — please confirm.”

2. AI Agent-Supported Quality Control

The AI agent monitors products in real time, detects irregularities, and immediately initiates corrective actions. By combining raw images with process parameters from PLCs, the agent dynamically refines inspection models and improves manufacturing accuracy on the fly. This reduces rejects, minimizes rework, and increases efficiency.

Difference to conventional AI: Conventional image processing AI can detect defects and, in some cases, retrain models over time. However, this usually happens in isolation. Follow-up actions such as adjusting machine parameters or updating quality protocols often require manual intervention. An AI agent augments this by coordinating the entire response across connected systems. In other words:

- Today’s AI = “This product has a defect; someone should check the process.”

- AI agent = “This product has a defect; I adjusted inspection parameters, updated the quality protocol, and notified the line manager for confirmation.”

3. Dynamic AI Planning Agent

A planning agent automatically adapts production schedules at short intervals based on live equipment status, material availability, and shifting priorities. Updates can occur every few minutes, keeping planning responsive to real-time conditions. The result: optimized throughput, better resource use, and shorter lead times.

Difference to conventional AI: Conventional planning tools, even if AI-supported, are usually based on periodic batch updates or manual planner input. They can suggest optimized schedules, but human operators still need to coordinate the changes. An AI agent augments this by continuously monitoring live data, recalculating the schedule automatically, and relaying updates directly to the MES. In other words:

- Today’s AI = “Here’s a better schedule; you might want to use it.”

- AI agent = “Here is the updated schedule; I will synchronize it with MES, ERP and line controllers after your confirmation.”

Challenges in Manufacturing

The successful deployment of AI agents in production requires meeting several key prerequisites:

1. Integration of legacy systems – AI agents depend on real-time data from machines and IT systems. In brownfield environments, proprietary protocols and missing interfaces hinder access.

2. Data quality – Reliable outcomes require consistent, context-rich data. Incorrect or unstructured inputs inevitably degrade results. As with all AI: garbage in, garbage out.

3. Limits and control mechanisms – Agents need clearly defined tasks and strict guardrails to act predictably and safely. Monitoring, audit logs, and intervention options ensure transparency and operator control.

4. Natural language interaction – Controlling agents via natural language boosts acceptance but requires robust language models to prevent misinterpretation — a critical IT/OT security factor.

5. Computing resources and infrastructure – High-performance hardware and stable edge/cloud infrastructure are essential. Insufficient resources cause latency, scalability issues, and failures in critical processes.

AI Agents in the Unified Namespace (UNS)

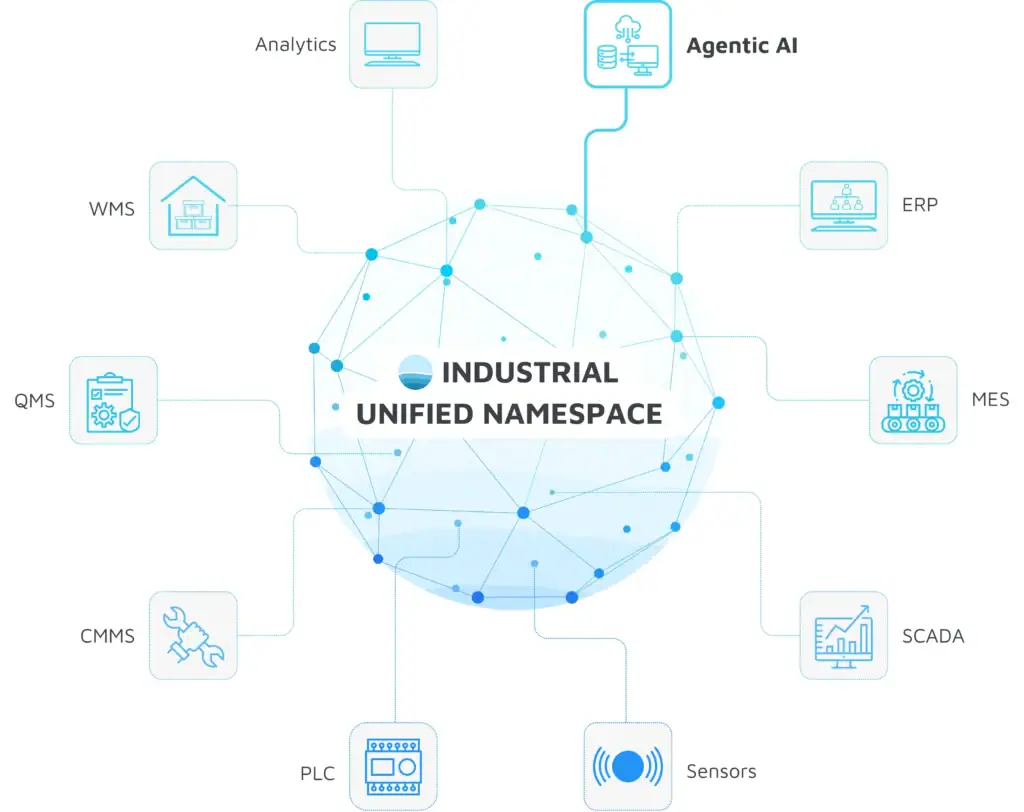

A Unified Namespace (UNS) is a centralized, structured data architecture that aggregates real-time information from the entire factory into a Single-Source-of-Truth. Machines, SCADA, MES, ERP, AGVs, and even forklifts publish their status and events to the UNS, where live data is available in a unified format.

This makes the UNS the ideal foundation for AI agents. Instead of pulling fragmented data from isolated systems, agents can subscribe to unified real-time data streams, enabling faster, more accurate decisions and optimized cross-system coordination. Tasks that once required complex, custom integrations and heavy engineering effort can now be handled through a single standardized interface.

Steps for Implementing AI Agents in the Unified Namespace (UNS)

The deployment of AI agents in the UNS requires clear objectives, robust data models, and a secure architecture. The following steps outline how an agent can be designed, implemented, and operated successfully.

Step 1: Define goal & scope

Every AI agent starts with a clear target definition. Benefits, KPIs, and boundaries must be specified to guide development and ensure measurable success. Planning agent example:

- Business goals: On-time delivery ↑ (95 %), lead time ↓, WIP ↓ (20 % WIP), OEE ↑, changeover times ↓ (-15 %), planning stability ↑.

- Scope: short-term detailed planning (0-72 h), sequencing, rush order control, bottleneck relief, “what-if” simulation.

- System boundaries: Agent reads status & master data (UNS/ERP/MES), writes new sequences/start times as proposal to MES/dispatcher (read-only → human-in-the-loop approach).

Step 2: Define requirements & constaints

Functional and non-functional requirements ensure reliable and compliant operation. These include KPIs, system constraints and regulatory requirements that enable safe operation. Planning agent example:

- Functional: react to machine malfunctions, schedule rush orders, simulation of alternative scenarios.

- Non-functional: planning duration < 60 s, 24/7 availability, auditability, deterministic repeatability.

- Compliance: alignment with site IT policies

Step 3: Structure data & knowledge

Agents require access to both real-time and historical data. Data must be modeled in the UNS for efficient context and retrieval. Planning agent example:

- Data sources:

- UNS: Current machine statuses, orders, maintenance windows, shift schedules

- SQL DB: Equipment and setup time matrices

- Relevant UNS topic examples:

- factory/{site}/{area}/{cell}/state (machine status)

- factory/{site}/{area}/{cell}/maintenance/schedule (maintenance window)

- factory/{site}/{area}/planning/orders/{orderId} (orders)

- factory/{site}/{area}/planning/shifts/{shiftId} (shifts)

- Payloads: JSON objects for orders, machine statuses, etc.

Step 4: Define architecture

The architecture determines how the agent is structured, which components are involved and how data flows are controlled. It is also important to establish clear security mechanisms. Planning agent example:

- Agent-Core (LLM): plans, explains, orchestrates tools.

- Solver: CP-SAT/MILP/heuristics (e.g. OR-tools) for sequencing and setup optimization.

- Gateway: UNS client, SQL adapter.

- Security: Write permissions only for UNS Topic …/planning/proposals/…

- Observability: Tracing of prompts, solver inputs/outputs, KPI metrics.

Step 5: Model & prompt design

Prompts and tools must guide the agent consistently within defined guardrails. Guardrails ensure that it only acts within the intended framework. Planning agent example:

-

- System prompt: “Planning agent” role with clear optimization goals (1. schedule adherence, 2. minimize setup changes, 3. minimize WIP).

- Tools:

- read_uns (topics) for reading data from the UNS

- solve_schedule (orders, resources, changeovers, objectives) for transferring the data to an optimization solver

- publish_proposal (schedule, rationale, kpiDelta) to publish the new production plan in a UNS Topic

- Guardrails: proposals only (no direct machine commands); escalation required for major postponements

After concept design, a prototype is tested in a defined scenario to validate the full data flow. Pilot phases, fallback mechanisms, and comprehensive testing ensure stable rollout. During operation, monitoring, regular data/model updates, and KPI tracking maintain performance. Transparent documentation, audit trails, and human oversight ensure trust, compliance, and security.

Best Practices for UNS-based AI Agents

The effective use of AI agents in industrial environments relies on a robust, standardized data foundation. Following proven best practices ensures reliable, scalable, and secure operation within a Unified Namespace (UNS):

| # | Best Practice | Description |

|---|---|---|

| 1 | Single Source of Truth | Uniform communication standard (e.g. UNS) across all systems for consistent data. |

| 2 | Data quality & integrity | Continuous validation, cleansing, and updates to ensure reliable results. |

| 3 | Least privilege | Broad read access, write access only to authorized endpoints. |

| 4 | Data with context | Metadata (timestamp, device ID, location) for traceability and AI interpretation. |

| 5 | Security by design | Use of encryption, authentication and access controls throughout the stack to protect sensitive data. |

| 6 | Human-in-the-loop (HiTL) | Manual release for critical or irreversible actions. |

| 7 | Guardrails | Content and action whitelists, policy checks before “risky” steps. |

| 8 | End-to-end tracing | End-to-end tracking of prompts, tool calls and decisions. |

| 9 | Drift management | Monitoring and detection of agent drift with regular re-indexing/updates. |

| 10 | Audit trails | Reproducibility of all relevant decisions (inputs, seeds, parameters). |

Conclusion

AI agents in the Unified Namespace (UNS) combine the strengths of LLMs with real-time data, tools, and defined processes — taking industrial AI to the next level. Beyond analysis, they actively coordinate processes in production, quality, and maintenance. Success, however, depends on a robust data foundation, clear roles and security mechanisms, and human oversight in critical decisions. By following best practices, companies can establish reliable, scalable, and trustworthy AI agents that create real value in today’s and tomorrow’s factories.