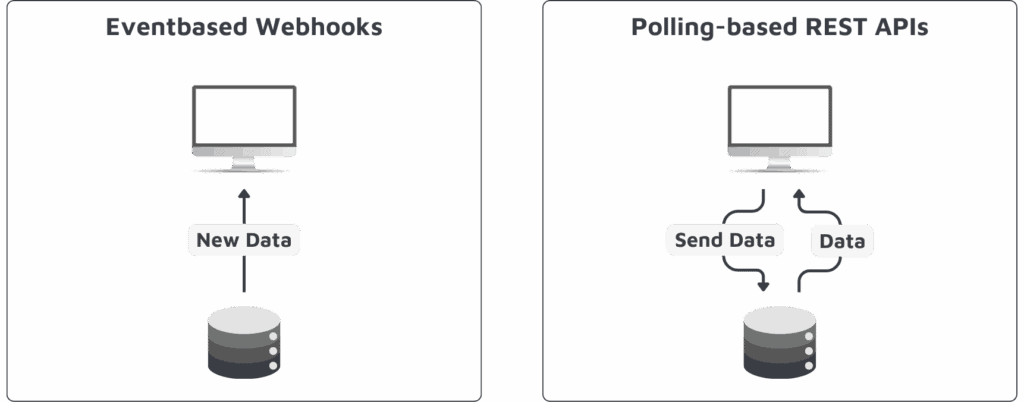

Digitalization demands architectures that deliver production data to IT and cloud systems in real time, securely and with context. Traditional polling-based REST APIs are often ill-suited for IT/OT integration: they create network and resource overhead, add latency, and scale poorly in OT environments. By contrast, MQTT and the Unified Namespace (UNS) enable event-driven architectures that efficiently orchestrate data flows between IT and OT. Yet, HTTP interfaces remain essential, since many enterprise systems, cloud platforms, and third-party applications still rely on established HTTP standards. Industrial APIs address this gap by combining the efficiency of event-driven communication with the broad compatibility of HTTP, making production data available in a standardized, secure, and event-based manner for systems such as ERP, MES, or analytics.

Limitations of Traditional REST APIs in the IT/OT Context

In IT/OT integration, productivity, flexibility, and innovation depend on the reliable exchange of real-time data. Use cases such as condition monitoring, digital twins, or AI-driven production optimization require continuous data streams with millisecond response times.

Traditional REST APIs, however, were designed for transaction-oriented IT workloads like authentication, reporting, or master data synchronization. These scenarios are typically stateless, request/response-based, and tolerate query intervals of seconds or even minutes – latency has little impact. In OT environments, the requirements are fundamentally different, exposing REST APIs to key limitations:

- Polling overhead: REST relies on active client polling to detect changes. This creates constant network traffic, even when no new data is available.

- Increased latency: Time gaps between a machine state change and the next polling request delay the detection of critical events such as failures or quality deviations.

- Resource inefficiency: Continuous polling consumes CPU and memory on both server and client. In edge or PLC environments with limited compute resources, this quickly becomes a bottleneck.

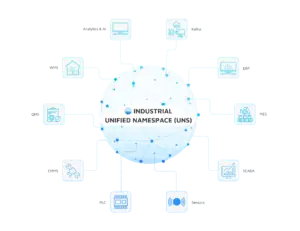

Unified Namespace (UNS) as the Basis for Industrial APIs

The limitations of REST and other polling based protocols can be addressed with an event-driven architecture built on a Unified Namespace (UNS). The UNS aggregates production and business data in a semantically structured namespace and distributes updates via publish/subscribe mechanisms. Using broker technologies like MQTT, it enables scalable, decoupled communication between OT and IT systems. This architecture establishes a single source of truth (SSOT) where machines, sensors, historian systems, and ERP applications publish their data once, while MES, analytics tools, or AI agents can subscribe in real time—without adding load to the source systems. As a result, the UNS provides the foundation for seamless IT/OT integration and the ideal backbone for industrial APIs.

Industrial APIs: Function and Advantages

On the basis of the Unified Namespace (UNS), industrial APIs are no longer fixed REST endpoints with polling, but event-driven interfaces that trigger UNS data pipelines in real time. These pipelines can:

- Read live values from the UNS

- Perform calculations or KPI generation

- Enrich data with context or route it to other systems

- Optionally return structured results via API

The trigger mechanism is implemented via Webhooks: a connected system (e.g., MES, ERP, or AI agent) sends an HTTP request, and the pipeline instantly aggregates and processes the relevant UNS data before returning the response. This enables on-demand access to consolidated, real-time production data — without polling overhead or proprietary point-to-point integrations.

Why Webhooks?

The key difference between REST APIs and Webhooks lies in the communication pattern:

- REST is request/response-based and relies on polling. Clients must repeatedly query for updates, which adds overhead, increases latency, and scales poorly with high-frequency shop floor data.

- Webhooks, are event-driven: when a defined event occurs, the system pushes an HTTP message to registered recipients. Data transfer is immediate, push-based, and requires no repeated requests.

In industrial IT/OT integration, this makes REST suitable for transactional queries (e.g., master data or configurations), while webhooks provide an efficient bridge to deliver MQTT events or UNS data into existing HTTP-based IT systems—in real time and with minimal overhead.

Industrial API Patterns

On a Unified Namespace (UNS), industrial APIs follow two main patterns—both going far beyond classic CRUD endpoints. Each call triggers a pipeline that leverages the full UNS context, including real-time values, metadata, and optionally historical enrichment.

- Request/Response APIs: An external client (e.g. MES, ERP, AI agent) calls a webhook and waits for a structured JSON result. The pipeline aggregates and processes live UNS data before returning the response. Ideal for on-demand retrieval of current machine states, KPIs, or contextualized production data.

- Fire-and-Forget APIs: The client triggers a webhook, but the pipeline runs asynchronously in the background. No response is expected. Suitable for non-critical, decoupled processes such as notifications, logging, or batch tasks.

Advantages of Industrial APIs

Beyond efficiency and scalability, webhook-based APIs excel through dynamism and context awareness. Unlike static endpoints, they process input data (parameters, query strings, JSON bodies) to control pipeline behavior in the UNS. A single API can serve multiple scenarios:

- Target selection: Parameters specify which machine or resource to address (e.g. machine ID).

- Data filtering: Queries define time ranges or scopes (e.g. “last 60s”). The pipeline then adapts its data provision dynamically.

- Conditional logic: Inputs such as mode=simulated control execution paths (e.g. test vs. live data). Instead of real actuator commands, only test data is generated and run through.

This input awareness makes industrial APIs context-adaptive. Instead of maintaining numerous specialized endpoints, one intelligent endpoint that can be flexibly extended via parameterization is sufficient. Scaling is achieved through parameterization, not through interface multiplication.

Architecture Example: i-flow Unified Namespace (UNS)

Industrial use cases demand varying levels of latency, availability, and security. To meet these needs, APIs must be provided not only centrally but also decentrally at the edge — ensuring the right execution model for each use case.

Central API Provision via the Hub

i-flow Edges deployed across plants register their available webhook APIs in the i-flow Hub. The Hub acts as the single API interface for the entire Unified Namespace (UNS). External calls are routed through the Hub, which orchestrates pipeline execution on the edges. This provides centralized control with full access to distributed pipelines and systems.

When to use:

- Single endpoint: External systems connect via one standardized API instead of managing multiple edge addresses.

- Central control, local execution: APIs are centrally reachable, while logic executes on distributed i-flow Edges.

Local API Provision on the Edge

In addition, edge instances can expose APIs directly within the plant network. These endpoints are independent of the Hub and ensure maximum proximity to shopfloor systems.

When to use:

- Offline capability: APIs remain available even if central connections fail, keeping critical processes running.

- Direct local integration: MES, SCADA, or HMIs connect with minimal latency and without complex firewall rules.

Hybrid Approach

The hybrid model combines central orchestration with local availability. The same API endpoints are accessible both via the Hub and directly at the Edge. For API consumers, this ensures consistent functionality – whether accessed from the cloud, a central data center, or directly within the plant network.

Central API Management with the i-flow Hub

In industrial environments, APIs need more than endpoint provisioning. Because they can directly affect physical processes, governance, monitoring, and lifecycle management are critical. The i-flow Hub provides this central control layer:

- API Governance: Consistent rules for authentication, naming, and versioning ensure uniform operation and compliance across all APIs.

- Monitoring: Every API call is tracked—status, latency, and execution location—along with input data (parameters, payloads). This creates a complete audit trail that not only fulfills regulatory requirements, but also enables debugging and replay of API calls.

- Deployment & Lifecycle Management: New or updated API pipelines can be deployed to Edges directly from the Hub. Versioning and rollback mechanisms guarantee controlled, reproducible operations.

Industrial APIs in Practice

A production planning tool incorporates live information from production into every new plan. Via a webhook-based request/response API, it triggers a pipeline in the Unified Namespace (UNS) on demand:

- Pipeline design: The pipeline aggregates machine data from the UNS – e.g. current system statuses, capacity utilization and material availability.

- Data enrichment: Contextual information from shift planning (working hours, staff availability, qualifications) is added.

- Planning API: The result is returned as a structured JSON that combines all relevant live data with shift context.

Practical Benefits:

- The planning tool receives a complete, up-to-date view of the current production situation on-demand.

- Enables realistic, context-aware planning based on machines, materials, and staff.

- The same end point can be used across production areas via parameters (e.g. line=pressing plant1 or period=shift2) without developing new interfaces.

Real-world Example

Discover how Sto SE & Co. KGaA, a global leader in building coatings, leverages i‑flow Industrial APIs to interconnect systems and production worldwide. By implementing i‑flow’s Unified Namespace (UNS) as a central data hub, Sto enables interoperability in its extensive IT/OT landscape across its global partner network. Read the full story here.

Conclusion

Industrial APIs in the Unified Namespace (UNS) bridge the gap between event-driven OT communication and standard HTTP in IT. Classic REST APIs, while effective for transactional IT workloads, fall short on the shop floor due to latency, scalability, and real-time demands. Webhook-based UNS APIs overcome these limits by delivering contextualized, secure, on-demand production data—without polling overhead and with flexible parameterization.

For architects, this means replacing fragmented, proprietary interfaces with a unified access layer to live data that serves both central IT systems and local shop floor applications. Building on the UNS and enabling event-based APIs provides the foundation for seamless IT/OT integration and future-ready factory architectures.